Let's discuss the plunger and barrel system found in fuel injection pumps.

Understanding the Plunger and Barrel

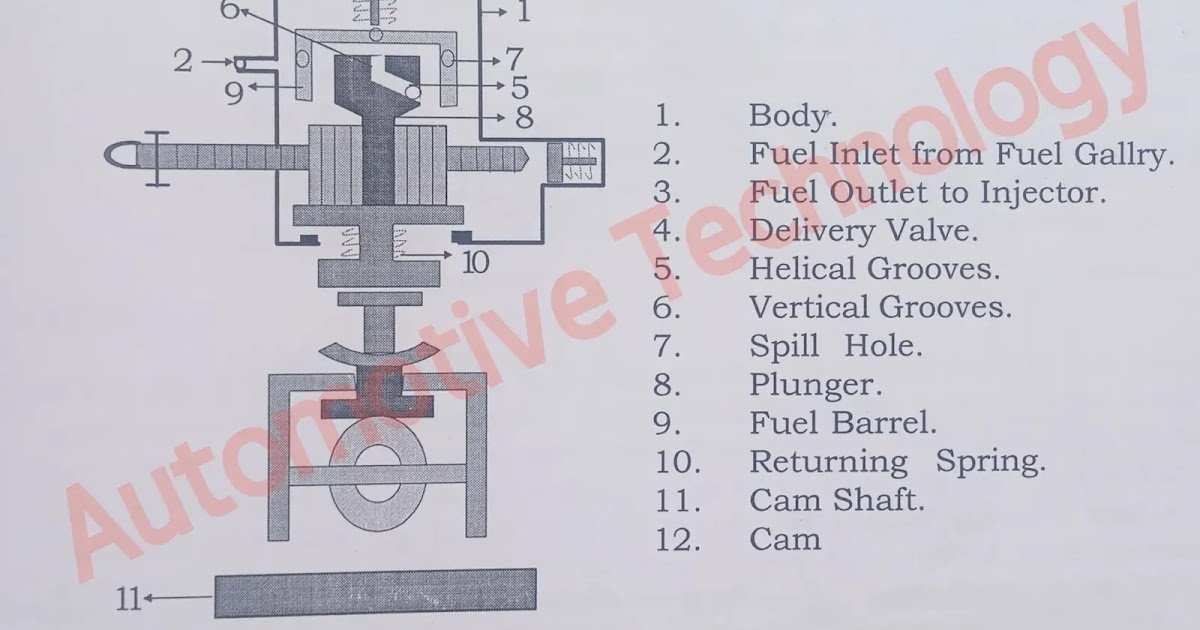

The plunger and barrel are critical components. They precisely meter fuel for injection into the engine cylinders. Understanding their function is essential for comprehending diesel engine operation.

The barrel is a precisely machined cylinder. It forms the housing for the plunger. The fit between the two is extremely tight.

The plunger is a close-fitting cylindrical component. It moves within the barrel. This movement controls fuel delivery.

How It Works

The plunger moves up and down (reciprocates) within the barrel. This action is driven by the pump's camshaft or similar mechanism. The reciprocating motion creates pressure.

Fuel enters the barrel through ports. The plunger's movement covers and uncovers these ports. This action determines the start and end of fuel injection.

A helical groove (or similar design) on the plunger interacts with the ports. As the plunger rotates, it effectively changes the timing and duration of the fuel delivery. This allows for precise control of the injected fuel quantity.

Teaching Strategies

Start with a visual aid. A cutaway model of a fuel injection pump is invaluable. This demonstrates the plunger and barrel's location and operation within the pump.

Use animations or simulations. These can clearly illustrate the plunger's movement and port coverage. This helps students visualize the fuel metering process.

Relate the concept to real-world applications. Discuss how the plunger and barrel system affects engine performance and fuel efficiency. This contextualizes the learning.

Incorporate hands-on activities. If possible, allow students to disassemble and reassemble a simplified fuel injection pump. This reinforces understanding through practical experience.

Addressing Common Misconceptions

Many students believe the plunger simply pushes fuel into the cylinder. Emphasize that it's the precise metering and timing, not just brute force, that's crucial. The barrel and its ports play a critical role.

Some may think the plunger itself creates the high pressure. Clarify that the pressure is a result of the rapid reduction in volume within the barrel when the ports are closed. The tight fit prevents leakage, allowing pressure to build.

Students might underestimate the importance of precision. Highlight the extremely tight tolerances between the plunger and barrel. Explain how even slight wear can significantly impact engine performance.

Making it Engaging

Use case studies of engine performance problems. Show how issues with the plunger and barrel can lead to misfires, reduced power, or excessive smoke. Students can then diagnose potential causes.

Incorporate interactive quizzes and polls. Check for understanding throughout the lesson. These activities keep students engaged and provide immediate feedback.

Challenge students to design improvements to the system. This could involve optimizing the port design or the plunger's helical groove. Encourage creative problem-solving.

Introduce the concept of electronically controlled fuel injection. Explain how sensors and actuators have replaced some mechanical components. This shows the evolution of fuel injection technology and connects it to modern systems.

Invite a guest speaker. A diesel mechanic or engine specialist can share real-world experiences. This adds credibility and provides valuable insights.

Key Takeaways

The plunger and barrel work together for precise fuel metering. The plunger's reciprocating and rotating motion control fuel delivery. Understanding this system is crucial for diagnosing and repairing diesel engines. Effective teaching involves visual aids, hands-on activities, and addressing common misconceptions. Remember the extreme precision required for this system to function properly.

The interaction between the plunger and the ports in the barrel is key to regulating both the quantity and timing of fuel injection. The helical groove on the plunger enables this precise control by altering the effective stroke length as the plunger rotates.

It's important to emphasize that the entire system relies on extremely high precision manufacturing. The minute clearances between the plunger and barrel are essential for maintaining the necessary pressure and preventing fuel leakage. Any wear or damage to these components can significantly impact engine performance.